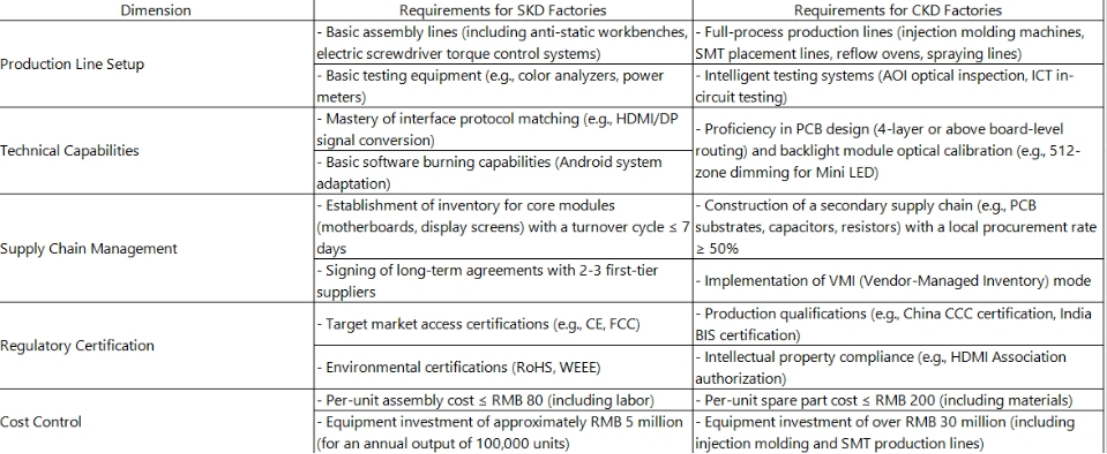

I. Core Definitions and Technical Features

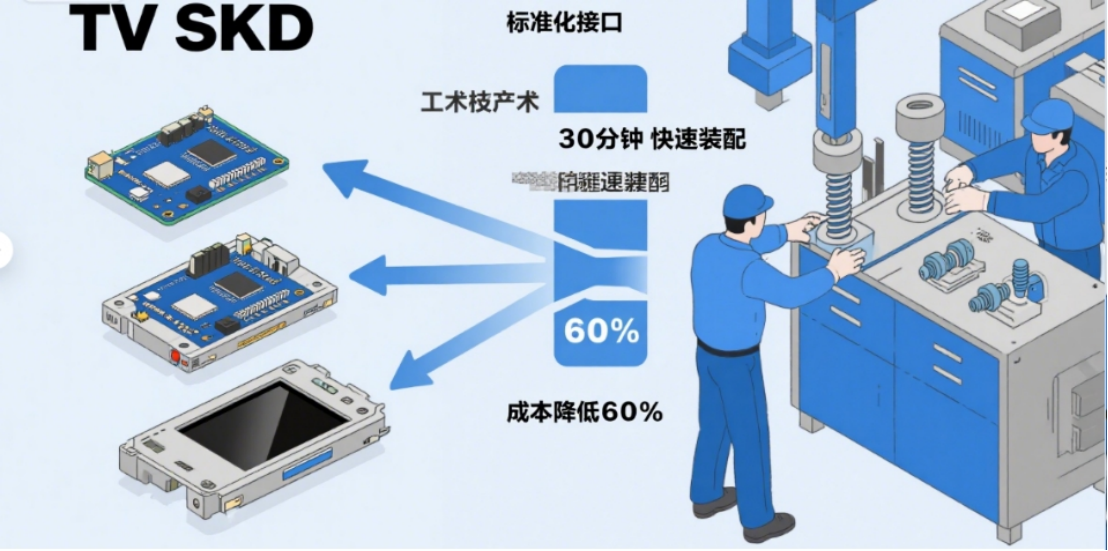

1. TV SKD (Semi – Knocked Down)

It refers to an assembly mode where core TV modules (such as motherboards, display screens, and power boards) are assembled via standardized interfaces. For example, the SKD production line of Guangzhou Jindi Electronics can be adapted to 40 – 65 inch LCD TVs of mainstream brands like Hisense and TCL, and upgrades can be completed by replacing the motherboard and adapting the software. Its core features include:

Modular Design: Adopts a “motherboard + display screen + housing” ternary structure, compatible with over 85% of brand models.

Basic Function Reuse: Retains the original power supply and backlight system, only replacing the core control module, which reduces costs by more than 60% compared to full machine replacement.

Rapid Adaptation: Plug – and – play is realized through unified interface protocols (e.g., HDMI 2.1, USB – C), shortening the installation time to within 30 minutes.

2. TV CKD (Complete Knocked Down)

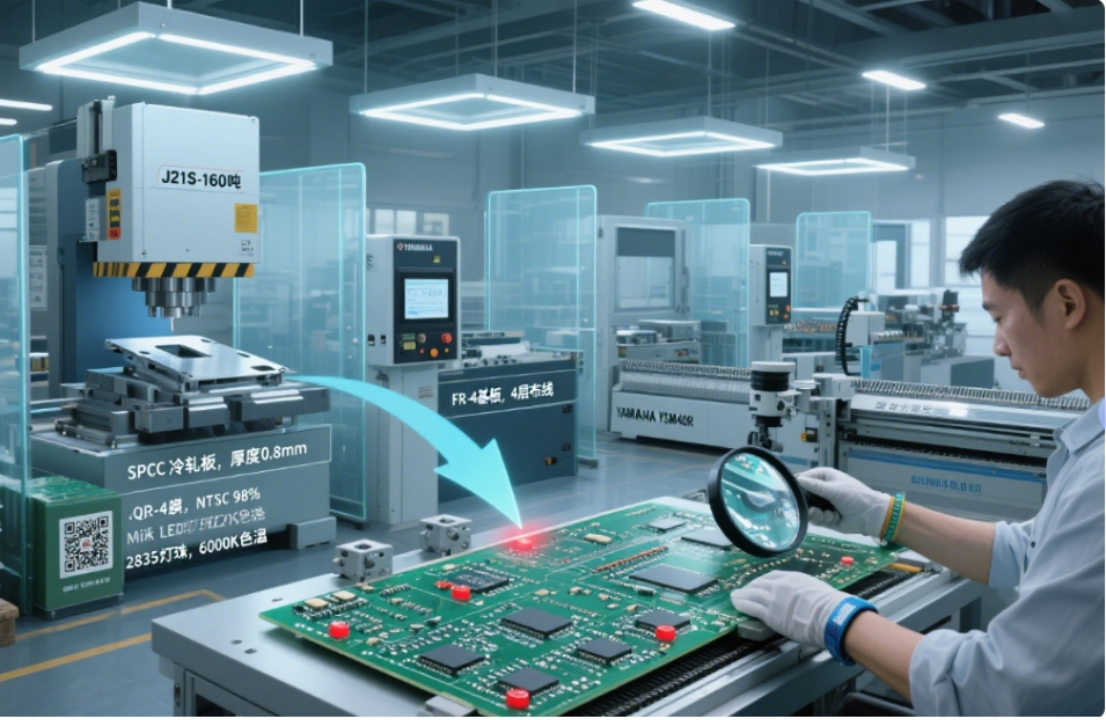

It refers to the mode where a TV is completely disassembled into spare parts (such as PCB bare boards, capacitors, resistors, and housing injection – molded parts), and the full – process production is completed locally. For example, the CKD production line of Foshan Zhengjie Electric covers processes such as injection molding, spraying, and SMT placement, with an annual output of 3 million sets of spare parts. Its core features include:

Full – Chain Localization: From steel plate stamping (for housings) to PCB welding (for motherboards), all processes are completed locally, with the local supply chain accounting for up to 70%.

In – depth Technical Integration: Mastery of core processes such as backlight module packaging and EMC (Electromagnetic Compatibility) design is required. For instance, Junhengtai’s 4K high – color – gamut solution needs to integrate quantum dot films and driver chips.

Policy Sensitivity: Compliance with target market regulations is necessary. For example, exports to the EU require CE certification (LVD Low Voltage Directive + EMC Electromagnetic Compatibility Directive), and the U.S. market requires FCC – ID certification (for wireless functions).

II. Comparison of Factory Access Conditions

III. Industry Application Scenarios and Cases

1. Typical Scenarios for SKD

Maintenance Market: Data from an e-commerce platform shows that the monthly sales volume of universal motherboards exceeds 500 units, with user feedback such as “easy installation” and “significant performance improvement”.

Upgrades in Emerging Markets: African countries use the SKD mode to upgrade 5-year-old CRT TVs to smart LCD TVs, with costs only 1/3 of new TVs.

Inventory Liquidation: Brands refurbish inventory TVs through the SKD mode. For example, a manufacturer upgraded its backlogged 2019-model TVs to 2023 models, increasing profit margins by 15%.

2. Typical Scenarios for CKD

Tariff Avoidance: Mexico’s USMCA (United States-Mexico-Canada Agreement) requires tariffs on TV spare parts to be ≤ 5%, while tariffs on complete TVs reach 20%, prompting Chinese enterprises to establish CKD factories in Mexico.

Technology Export: Junhengtai exported a 4K TV CKD solution to Uzbekistan, including production line design, worker training, and supply chain construction, realizing technology overseas expansion.

Local Compliance: India’s “Phased Manufacturing Program” requires the CKD assembly ratio to increase year by year, reaching 60% by 2025, forcing enterprises to establish secondary supply chains in India.

IV. Technical Trends and Risk Tips

1. Directions of Technical Evolution

Penetration of Mini LED and OLED: TCL’s C6K QD-Mini LED TV adopts 512-zone dimming, requiring CKD factories to master quantum dot film lamination technology; the self-illuminating feature of OLED panels simplifies the backlight module but imposes higher requirements on packaging processes.

Popularization of 8.6th-Generation Production Lines: Enterprises such as BOE and Visionox have expanded 8.6th-generation OLED production lines, with cutting efficiency 106% higher than that of 6th-generation lines, forcing CKD factories to upgrade equipment.

Intelligent Integration: SKD motherboards need to integrate AI voice chips (e.g., far-field voice recognition), and CKD requires the development of multi-modal interaction systems (gesture + touch control).

2. Risks and Countermeasures

Intellectual Property Barriers: HDMI Association authorization fees account for 3% of the cost of SKD motherboards; enterprises need to reduce risks through cross-licensing of patents.

Supply Chain Volatility: Display screen prices are affected by panel factory production capacity (e.g., Samsung’s reduction in OLED production); CKD factories need to establish a dual-source procurement mechanism.

Policy Changes: The EU’s New Battery Regulation requires supply chain traceability; CKD factories need to implement a blockchain-based material tracking system.

V. Typical Enterprise Cases

1. SKD Representative: Guangzhou Jindi Electronics

Technical Advantages: Independently developed 4-core 1.8GHz processor motherboards, supporting 4K 60Hz decoding and compatible with the Android 11 system.

Market Strategy: Bundled sales of “motherboards + software”, with a gross profit margin of 40%, higher than the industry average of 25%.

2. CKD Representative: Sichuan Junhengtai

Innovation Breakthrough: Cooperated with Zhejiang University to develop all-solid-state perovskite backlight technology, with an NTSC color gamut of 97.3%, 4.3% higher than traditional solutions.

Business Model: Provided “equipment leasing + technology authorization” services to African customers, with an annual service fee of USD 2 million per production line.

Post time: Sep-08-2025