1. Core Definition & Composition

Open Cell mainly consists of an LCD panel, color filter, polarizer, driver ICs, and a PCB (Printed Circuit Board). However, it lacks key components of a complete panel, such as the backlight module and power elements. Acting as the “core framework” for TV display, it serves as a critical intermediate product connecting upstream panel manufacturing and downstream TV assembly. After purchasing Open Cell, downstream manufacturers need to integrate it with custom backlight modules and other components to produce fully functional, display-ready TV panels.

2. Core Manufacturing Process

The production flow comprises three key stages, adhering to the rigorous standards of semiconductor and precision electronics manufacturing:

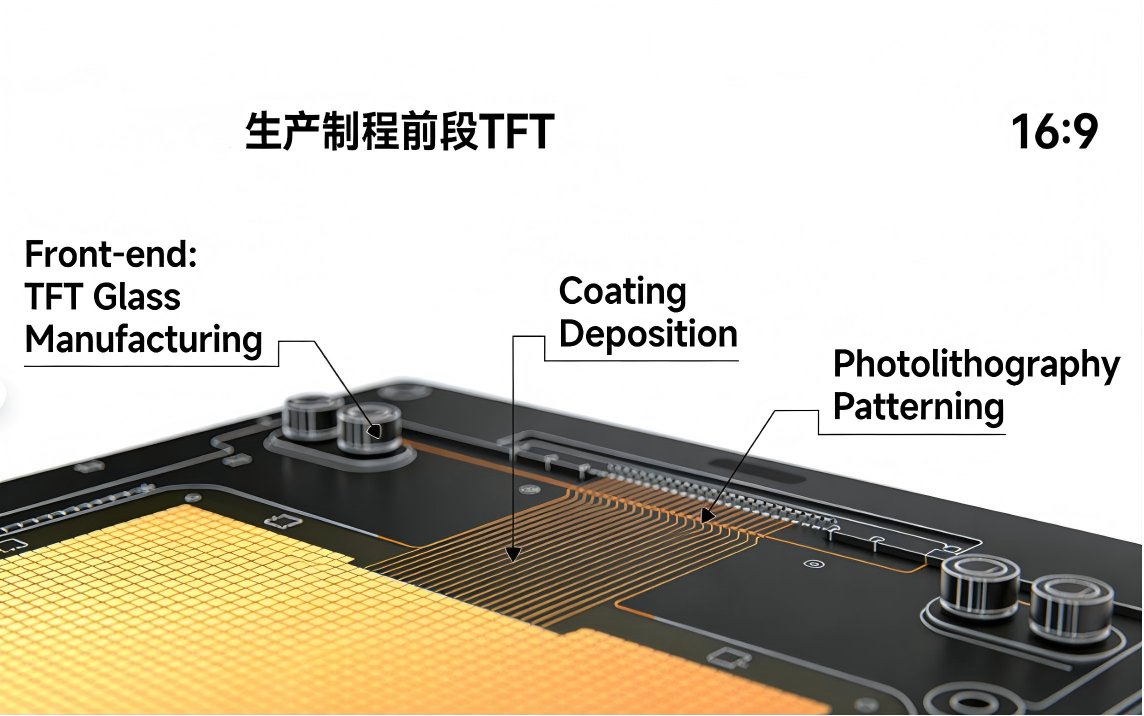

Front-end process: Focuses on TFT glass production, similar to semiconductor manufacturing. It involves coating, photolithography, and other processes to fabricate metal circuits and semiconductor layers.

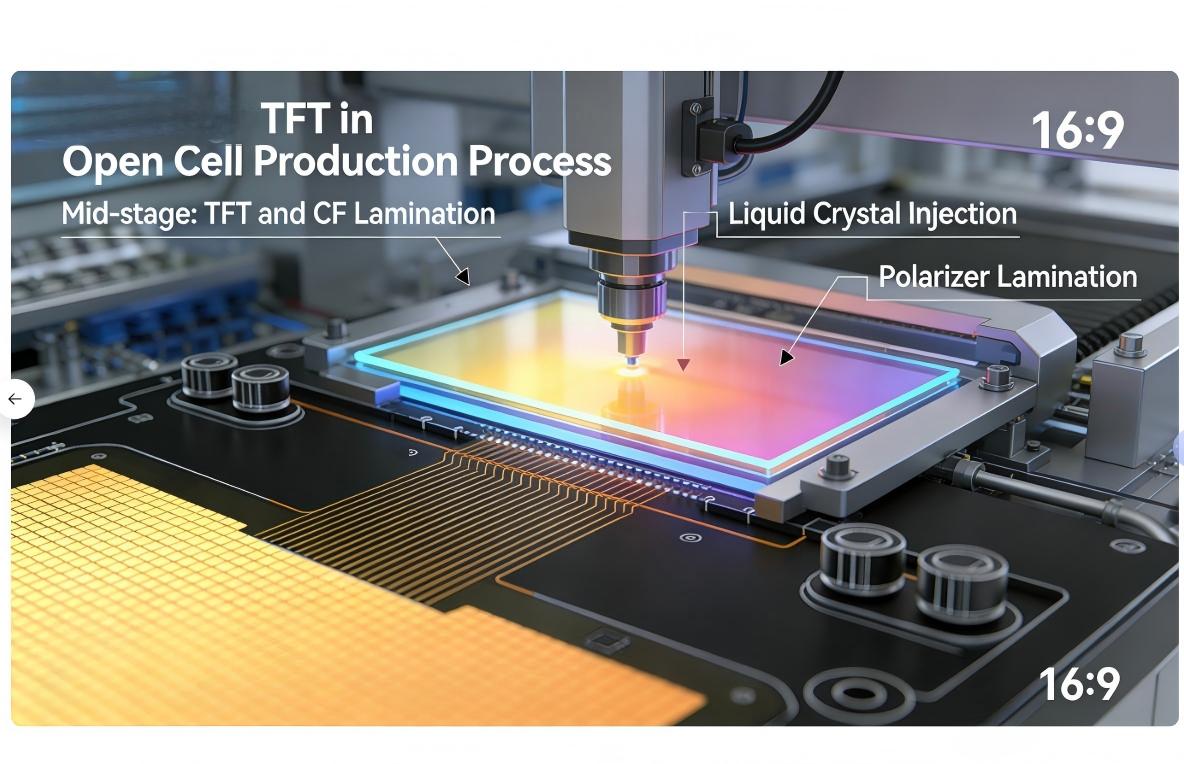

Middle-end process: Bonds the TFT glass with the color filter, applies alignment films, injects liquid crystal, and finally attaches polarizers.

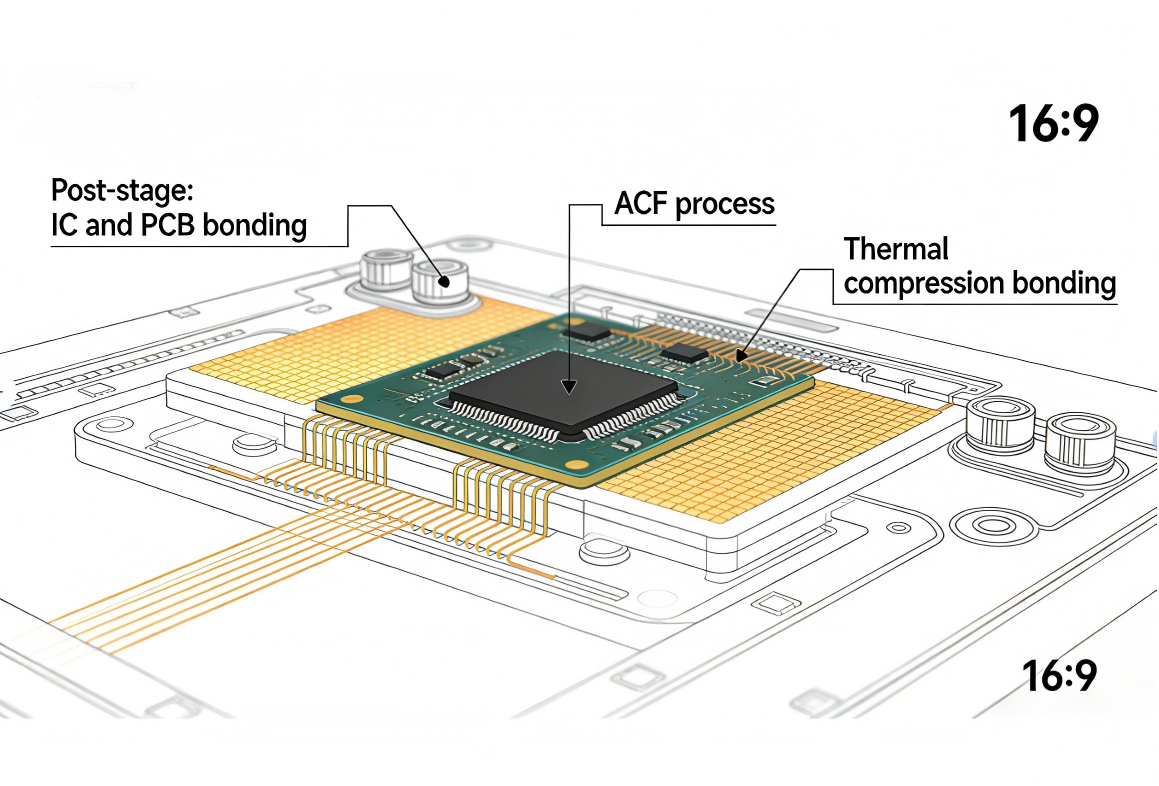

Back-end process: Bonds driver ICs and PCBs to the LCD panel using anisotropic conductive film (ACF), completing the final formation of Open Cell.

3. Key Reasons for Industry Adoption

For TV manufacturers: Procuring Open Cell and integrating custom backlight modules significantly reduces procurement costs. It also enhances product design flexibility—enabling the development of ultra-thin models or high-brightness TVs tailored to specific market positioning.

For panel manufacturers: Shipping Open Cell reduces material management costs and cash flow occupation associated with backlight modules. Additionally, Open Cell offers higher profit margins compared to complete modules. This model also aligns with downstream manufacturers’ integrated production lines (combining backlight and module assembly), shortening supply chain cycles.

4. Dual Impacts on the Industry

Advantages

Beyond cost benefits, Open Cell’s standardization eliminates the need for downstream manufacturers to repeatedly adjust production lines for different finished panel specifications. It enables integrated panel and TV assembly, supporting differentiated design innovations. For example, in 2025, Voyage Optoelectronics launched its OC Black Obsidian Film technology, which, combined with glass-based backlight design, significantly improves LCD contrast and anti-glare performance.

Disadvantages

This model reduces panel manufacturers’ control over the end market. Without the ability to differentiate products through customized module functions, panel prices are prone to accelerated declines during oversupply. Moreover, standardization makes it difficult for panel makers to establish competitive barriers via specification differentiation, potentially compressing the industry’s overall profit margins.

5. Current Market Applications

Open Cell has become the mainstream shipment format for LCD TV panels, with BOE Technology Group and CSOT (China Star Optoelectronics Technology) as core suppliers. The model is also expanding into the OLED sector—for instance, LGD previously planned to supply OLED Open Cell semi-finished products to Chinese TV manufacturers. In terms of capacity expansion, enterprises are accelerating : CSOT’s India factory has achieved mass production of 32-55 inch TV Open Cell, covering India and global emerging markets.

Post time: Dec-10-2025